About Us

About us

PuYang YRT Communication Technology Co., Ltd. was established in March 2008. The company's base is located in the industrial agglomeration area of Qingfeng County, Puyang City, Henan Province, covering an area of more than 60 acres and with an annual output value of 100 million yuan. Products are sold in thirty countries !

Date of establishment: 2008

Number of employees: 230

System certification: ISO9001, ISO14001, ISO45001

Production Line :22

Main products:

1 : Aerial Fiber Optic Cables such as : ADSS, ASU, Figure-8 Cables, and FTTH Drop Cables;

2 : Duct Fiber Optic Cables including : GYTA, GYTS, GYTY, GYFTY, GYFTA, and GYXTW;

3 : Direct Burial Fiber Optic Cables : GYTA53, GYFTA53, GYTY53, GYFTY53, and GYXTW53;

4 : Figure-8 Self-supporting Aerial Cables, including : GYXTc8S, GYXTc8Y, GYTC8A, GYTC8S, and GYFTC8Y;

5 : Air-blown Micro Fiber and Cable solutions: GCYFXTY, GCYFY, EPFU, SFU, and MABFU;

6 : FTTH Drop Cables: GJYXFCH, GJYXCH, GJXFH, GJXH, and GYFXBY;

7 : Anti-rodent and Anti-termite Fiber Cables: GYFTS, GYFTA53, GYFTA54, and GYFTA83;

8 : Submarine Fiber Optic Cables, Military or Field Application Cables, Ribbon-type Fiber Optic Cables, and more;

9 : ODN (Optical Distribution Network) products.

10 : Connectors: LC,SC,FC,ST . APC/UPC

11 : Adaptor :LC,SC,FC,ST,MPO .(LC-LC,SC-SC,SC-FC,MPO)

12 : Splitter :MINI PLC ,LGX PLC ,ABS PLC, FBT (1*2, 1*4, 1*8 , 1*16 ,1*32 ,1*64)

13 : Fiber optic box : Distribution Box , Splice Box ,Terminal Box ,ODF

"

"

Automated production lines, constant improving production efficiency,over 700,000 km fiber optical cables production experience,Over 5 million pcs patch cords production experience, The annual production capacity of our core product production line is as follows:

| PL | QTY | Products | Production Ability |

|---|---|---|---|

| Jumper Cable Line | 2 | Indoor patchcords, Armored patchcords, FTTH patch cords, MPO Patchcords, FTTA (remote)Patch cords, Water-proof patch cords, etc. | 300,000.00 PCS |

| Butterfly Cable Lines | 7 | FTTH, GJXH, GJYXCH, 1~4 CORES | 30000KM+ |

| Outdoor cable Lines | 4 | Central Loose Tube Cable,GYXTW,Armored Fiber cable,indoor optic cable ,FTTH drop cable | 10000KM+ |

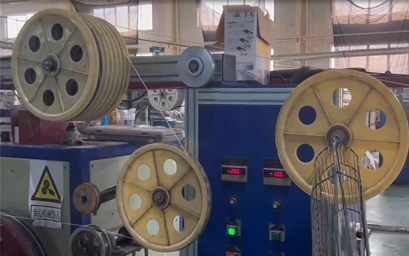

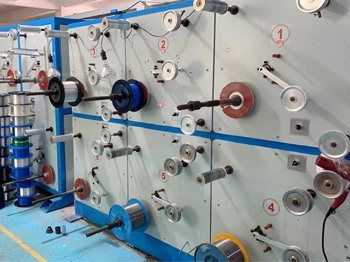

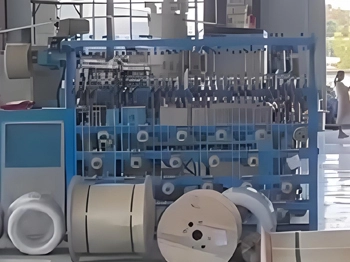

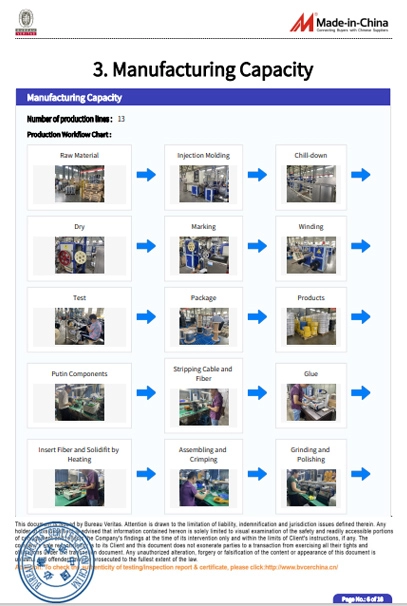

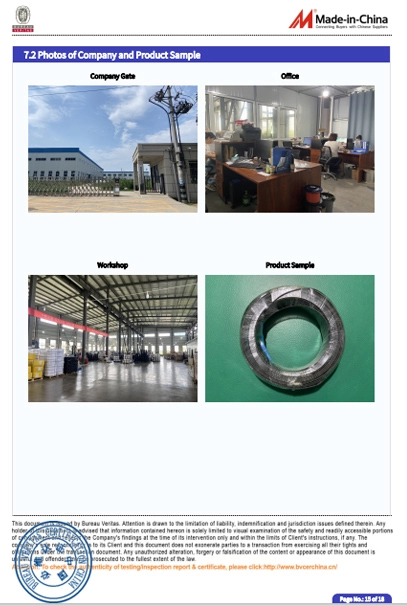

We have a total of 13 production lines, modernized dust-free workshops, and high-performance processing equipment. From raw material procurement, to finished product processing, to product quality testing, to packaging and export, we have a full range of production lines. The following are some of the actual photos of the workshop

Our production workshop is equipped with fully automated optical fiber and cable manufacturing equipment, including high-speed traction machines, precision stranding machines, cabling machines, extruders and tension control systems, covering the entire process from fiber optic reeling, cladding coloring to cabling, sheath extrusion and online testing. The equipment uses PLC centralized control and closed-loop feedback to ensure stable tension, precise dimensions and production capacity. With advanced online optical loss testing and aging test platforms, we can conduct strict quality inspections on each optical cable and deliver high-quality, high-reliability end-to-end network connection products to customers.

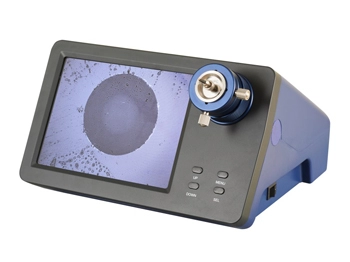

We have complete product quality and safety testing standards, and strictly implement product quality management, product performance reliability testing, supplier quality management, incoming material quality inspection (IQC), process/shipment quality inspection (IPQC), and have the following full set of product quality testing instruments. Because of our strict quality testing standards, we have won the high trust of our partners.The following are some product quality testing equipment.

This is a third-party audit report. Click to download the entire detailed report Download:Third-party audit report

The company;s management and production complies ISO9001 / ISO14001 / ISO45001 certifications.

We have in-depth cooperation with Corning, Changfei, FiberHome, Huawei and other world-renowned optical fiber and cable and communication equipment manufacturers, as well as China Mobile, China Unicom, China Telecom and CDSEI standardization organization. Relying on the technical and resource advantages of all parties, we continuously optimize the process and improve the quality, and work together to provide customers with efficient and reliable end-to-end network solutions to promote the innovative development of the industry.