optical properties

| G.652 | G.655 | 50 / 125μm | 62.5/125 μm |

| Attenuation (+20℃) | @850nm |

|

| ≤3.0 dB/km | ≤3.0 dB/km |

| @1300nm |

|

| ≤1.0 dB/km | ≤1.0 dB/km |

| @1310nm | ≤0.36 dB/km | ≤0.40 dB/km |

|

|

| @1550nm | ≤0.22 dB/km | ≤0.23dB/km |

|

|

| Bandwidth (Class A) | @850nm |

|

| ≥500 MHz·km | ≥200 MHz·km |

| @1300nm |

|

| ≥1000 MHz·km | ≥600 MHz·km |

| Numerical Aperture |

|

| 0.200±0.015NA | 0.275±0.015NA |

| Cable Cut-off Wavelength | ≤1260nm | ≤1480nm |

|

|

| Storage/Operating temperature | -40℃ ~+70℃ |

Technical parameters

Model | Fiber Count | Tubes | Fillers | Outer Diameter (mm) | Weight (kg/km) | Tensile Strength Long/short term N | Crush Resistance Long/short term N/100mm | Bending Radius Static/ Dynamic mm |

GYTY53-2~6F | 2~6 | 1 | 5 | 13.0 | 169 | 1690/3000 | 300/1000 | 10D/20D |

GYTY53-8~12F | 8~12 | 2 | 4 | 13.0 | 169 | 1690/3000 | 1000/3000 | 10D/20D |

GYTY53-14~18F | 14~18 | 3 | 3 | 13.0 | 169 | 1690/3000 | 1000/3000 | 10D/20D |

GYTY53-20~24F | 20~24 | 4 | 2 | 13.0 | 169 | 1690/3000 | 1000/3000 | 10D/20D |

GYTY53-26~30F | 26~30 | 5 | 1 | 13.0 | 169 | 1690/3000 | 1000/3000 | 10D/20D |

GYTY53-32~36F | 32~36 | 6 | 0 | 13.0 | 169 | 1690/3000 | 1000/3000 | 10D/20D |

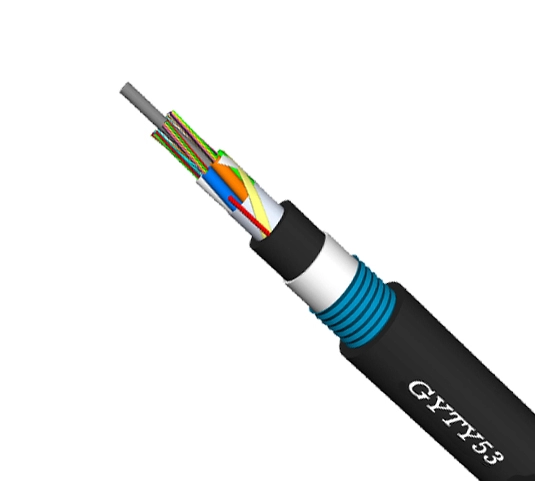

GYTY53 Stranded Loose Tube Armored Cable G652D Product Description

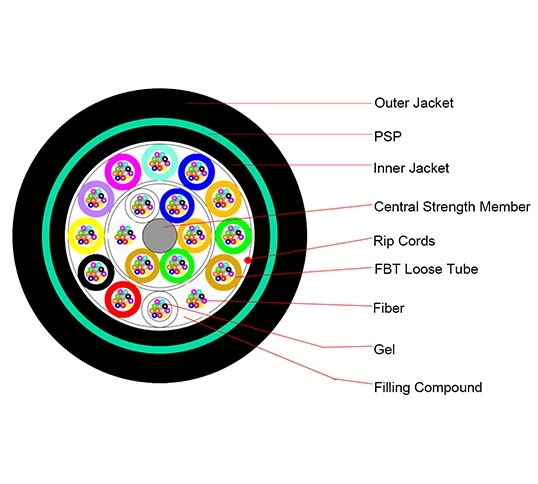

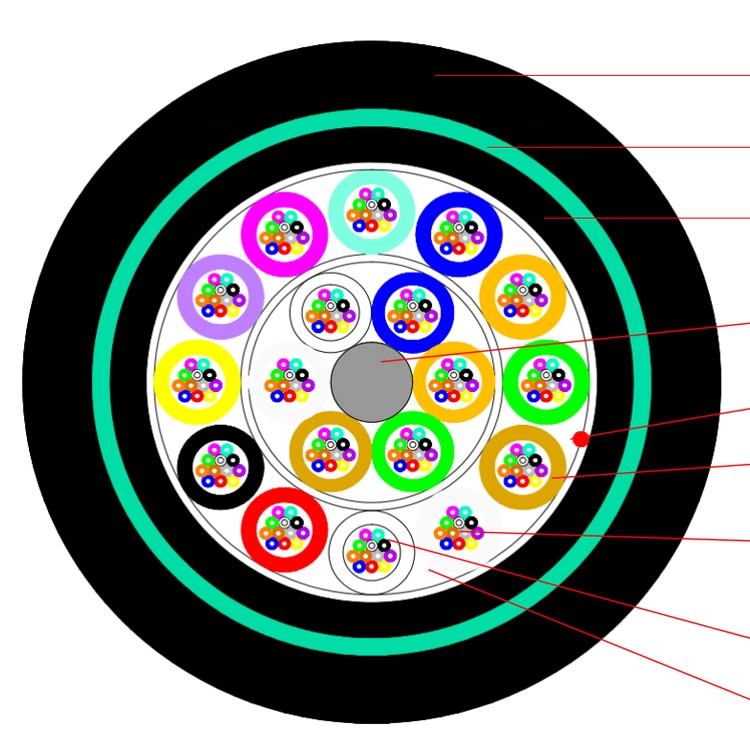

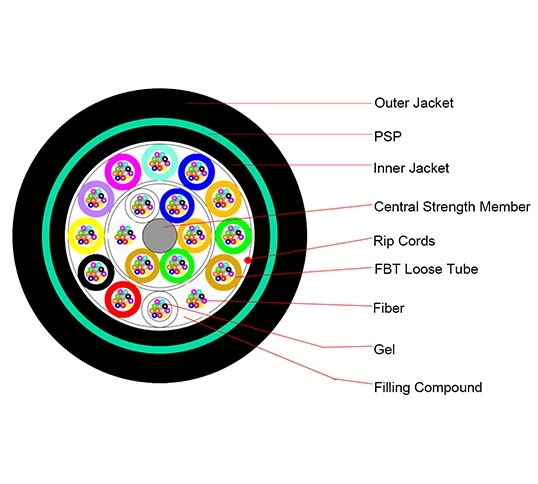

The GYTY53 type optical cable places the 250um optical fiber in a loose sleeve made of high modulus plastic, and the sleeve is filled with waterproof filler. The center of the core wire is a steel wire and a PE sheath. As a metal reinforcement, the sleeve and the filler are wound around the reinforcement to form a compact circular cable core. The filler fills the inside of the cable core to prevent water from entering, and the outer cover is a thin PE inner sheath. After the inner sheath covers the PSP in the longitudinal direction, the PE outer sheath is wrapped to form a cable.

Product features of GYTY53 Stranded Loose Tube Armored Cable G652D

Good mechanical properties, good high temperature resistance

Loose casing with high strength and resistance to hydrolysis

Special casing filler plays a key role in protecting optical fibers

Anti-extrusion, good flexibility

PSP enhanced moisture resistance

Good water resistance

English

English  Spanish

Spanish  Portuguese

Portuguese  Arabic

Arabic  Russian

Russian  简体中文

简体中文

Location:

Location:

Product Overview

Product Overview

Return to List

Return to List