Blog

blog Популярные запросы: patch cord single mode fiber fiber cable fiber optic Multimode optical cable single

Популярные запросы: patch cord single mode fiber fiber cable fiber optic Multimode optical cable single  Текущее местоположение: Home > Блог > Техническая статья

Текущее местоположение: Home > Блог > Техническая статья

Время обновления:2025-04-08

Время обновления:2025-04-08 Посещаемость:

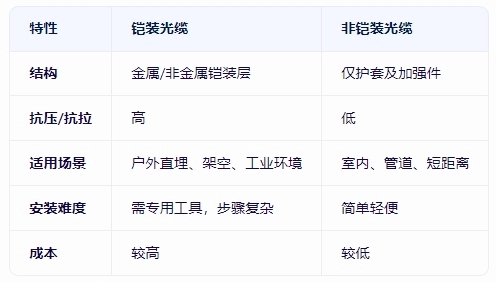

Посещаемость: The main differences between fiber optic ribbon (armored cable) and unarmored (unarmored cable) lie in the structural strength, applicable scenarios, and installation methods. The following are detailed comparisons:

1. Structural differences

armored cable

One or more layers of metal (e.g. steel strip, aluminum strip) or non-metal (e.g. aramid yarn) are added to the fiber sheath to enhance the mechanical strength of the cable.

Metal armor: strong resistance to compression and lateral pressure, suitable for high pressure environments.

Non-metallic armor (e.g. aramid): lightweight, high tensile strength, suitable for overhead or long-distance laying.

unarmored cable

Contains only optical fibers, sheaths, and possible reinforcements (e.g. glass fiber reinforced plastic FRP), without additional armor layers, and is lightweight in construction.

2. Capacity to protect

armored cable

Compression resistance/side pressure resistance: can withstand direct burial, vehicle rolling or pipeline extrusion.

Tensile resistance: suitable for overhead or long-distance spans (e.g. between power towers).

Anti-rodent: Metal armor protects against rat bites.

unarmored cable

Dependent on environmental protection: through pipes, trunks or indoor wiring, vulnerable to external damage.

Bending sensitivity: Without armor, excessive bending may result in increased fiber loss.

3. Application scenarios

armored cable

Outdoor direct burial: highway, railway, park underground wiring.

Overhead laying: high-altitude scenes such as power towers and bridges.

Pipeline complex environment: requires resistance to lateral pressure or rodent protection.

Industrial scenarios: corrosive environments such as chemical plants and oil fields (requiring special coatings).

unarmored cable

Indoor wiring: computer room, data center, building interior.

Pipe protection: Pipes or trunks that have been physically protected.

Short-distance jumper: Temporary connection between devices.

4. Installation and maintenance

armored cable

Tool requirements: Special cable opener is required (e.g. metal armor requires a ring cutting tool).

Installation difficulty: heavy and stiff, with strict bending radius requirements.

Grounding requirements: Metal armor needs to consider lightning protection grounding.

unarmored cable

Flexible and lightweight: easy to bend, suitable for tight spaces.

The tool is simple: ordinary fiber stripping pliers can be operated.

5. Cost comparison

Armored optical cable: Due to the complex material (metal/aramid) and process requirements, the cost is high.

Unarmored cable: simple structure and lower cost.

summarize

Selection suggestion:

If the cable needs to be exposed to harsh environments for a long time (e.g. buried or overhead), armored cables are preferred.

For indoor or protected pipe wiring, unarmored cables are more economical and practical.

995

995

Телефон: +86 027-65523878