Fiber Optic Splicer: Tools and Techniques for Seamless Connections

Update Time:2026-01-14

Update Time:2026-01-14

Traffic:

Traffic:

This article focuses on fiber optic splicers, which are crucial for fiber optic networks. It first emphasizes the importance of seamless connections in maintaining network integrity. Then, it differentiates between mechanical and fusion splicers, discussing their features and applications. Essential tools like fiber strippers, cleaving tools, and microscopes are also introduced. The article further details the fiber optic splicing process, including preparation, cleaving, alignment, splicing, and inspection. Overall, it provides a comprehensive overview of the tools and techniques for achieving seamless fiber optic connections.

Fiber Optic Splicer, Seamless Connections, Splicing Tools

- Importance of Seamless Fiber Optic Connections

- Types of Fiber Optic Splicers

- Mechanical Splicers

- Fusion Splicers

- Essential Tools for Fiber Optic Splicing

- Fiber Strippers

- Cleaving Tools

- Microscopes

- The Fiber Optic Splicing Process

- Preparation

- Cleaving

- Alignment

- Splicing

- Inspection and Protection

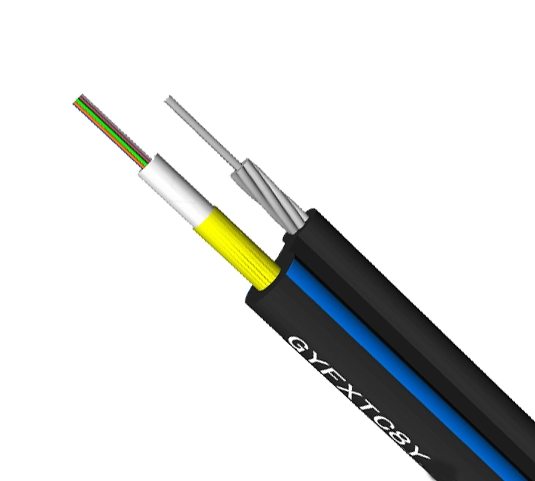

In the world of telecommunications and data transmission, fiber optic technology has revolutionized the way we communicate. At the heart of ensuring efficient and reliable fiber optic networks are fiber optic splicers. These devices play a crucial role in creating seamless connections between fiber optic cables, allowing for the uninterrupted flow of data at high speeds.

Importance of Seamless Fiber Optic Connections

Seamless fiber optic connections are essential for maintaining the integrity of a fiber optic network. Any discontinuity or loss in the connection can lead to signal degradation, increased attenuation, and ultimately, a decrease in the overall performance of the network. A high - quality splice minimizes these losses, ensuring that data can be transmitted over long distances with minimal interference.

Types of Fiber Optic Splicers

There are mainly two types of fiber optic splicers: mechanical splicers and fusion splicers.

Mechanical Splicers

Mechanical splicers use a mechanical alignment and clamping mechanism to join two fiber optic cables. They are relatively easy to use and do not require a power source. Mechanical splicing involves stripping the fiber, aligning it precisely within a splicing sleeve, and then securing it in place with a mechanical device. This type of splicing is often used for temporary or emergency repairs, as well as in situations where fusion splicing is not practical. However, mechanical splices generally have higher insertion losses compared to fusion splices.

Fusion Splicers

Fusion splicers are the most commonly used type of splicer in modern fiber optic networks. These devices use an electric arc to melt the ends of the two fiber optic cables and fuse them together. Fusion splicing creates a near - perfect molecular bond, resulting in very low insertion losses and excellent mechanical strength. Fusion splicers are equipped with precision alignment systems that ensure the fibers are perfectly aligned before the fusion process. They require a power source and some level of technical expertise to operate, but the results are well worth the investment in terms of network performance.

Essential Tools for Fiber Optic Splicing

In addition to the splicer itself, several other tools are required for a successful fiber optic splicing operation.

Fiber Strippers

Fiber strippers are used to remove the outer protective layers of the fiber optic cable, exposing the bare fiber. These tools are designed to strip the fiber cleanly without damaging the core or cladding. There are different types of fiber strippers available, including manual and automatic models.

Cleaving Tools

Cleaving tools are used to create a flat, perpendicular end on the bare fiber. A clean and precise cleave is essential for a successful splice. Cleaving tools use a diamond - tipped blade or a scoring mechanism to create a crack in the fiber, which is then broken to form a smooth end face. The quality of the cleave directly affects the performance of the splice, as any irregularities can lead to increased losses.

Microscopes

Microscopes are used to inspect the end faces of the fibers before and after splicing. Fiber optic microscopes provide a magnified view of the fiber end face, allowing technicians to check for any contaminants, scratches, or other defects. This inspection is crucial to ensure that the fibers are in good condition and that the splice will be of high quality.

The Fiber Optic Splicing Process

The fiber optic splicing process involves several steps:

Preparation

First, the fiber optic cables are prepared. This includes stripping the outer jacket and buffer layers using fiber strippers to expose the bare fiber. The bare fiber is then cleaned to remove any contaminants.

Cleaving

The next step is cleaving the fiber. The fiber is carefully positioned in the cleaving tool, and a clean, perpendicular cleave is made. The cleaved fiber is then inspected under a microscope to ensure its quality.

Alignment

For fusion splicing, the two cleaved fibers are aligned precisely in the fusion splicer. The splicer uses its alignment system to ensure that the cores of the fibers are perfectly aligned. In mechanical splicing, the fibers are aligned within the splicing sleeve.

Splicing

In fusion splicing, an electric arc is generated to melt the ends of the fibers and fuse them together. In mechanical splicing, the fibers are secured in place within the splicing sleeve using mechanical means.

Inspection and Protection

After splicing, the splice is inspected under a microscope to check for any defects. If the splice is satisfactory, it is then protected with a splice protector, such as a heat - shrink tube, to provide mechanical strength and prevent damage.

In conclusion, fiber optic splicers and the associated tools and techniques are vital for creating seamless fiber optic connections. Whether it's for building a new network or maintaining an existing one, understanding the different types of splicers, having the right tools, and following the proper splicing process are key to achieving high - quality, reliable fiber optic connections.

Q & A

What are the main types of fiber optic splicers?

Answer: The main types are mechanical splicers and fusion splicers.

What is the advantage of fusion splicers over mechanical splicers?

Answer: Fusion splicers create a near - perfect molecular bond, resulting in very low insertion losses and excellent mechanical strength compared to mechanical splices which generally have higher insertion losses.

What tools are needed for fiber optic splicing?

Answer: Fiber strippers, cleaving tools, and microscopes are essential tools for fiber optic splicing.

Why is a clean cleave important in fiber optic splicing?

Answer: A clean and precise cleave is essential for a successful splice as any irregularities can lead to increased losses.

How is the splice protected after fiber optic splicing?

Answer: After splicing, if the splice is satisfactory, it is protected with a splice protector like a heat - shrink tube to provide mechanical strength and prevent damage.

English

English  Spanish

Spanish  Portuguese

Portuguese  Arabic

Arabic  Russian

Russian  简体中文

简体中文

Location:

Location: